Additive Manufacturing: A technology with potential

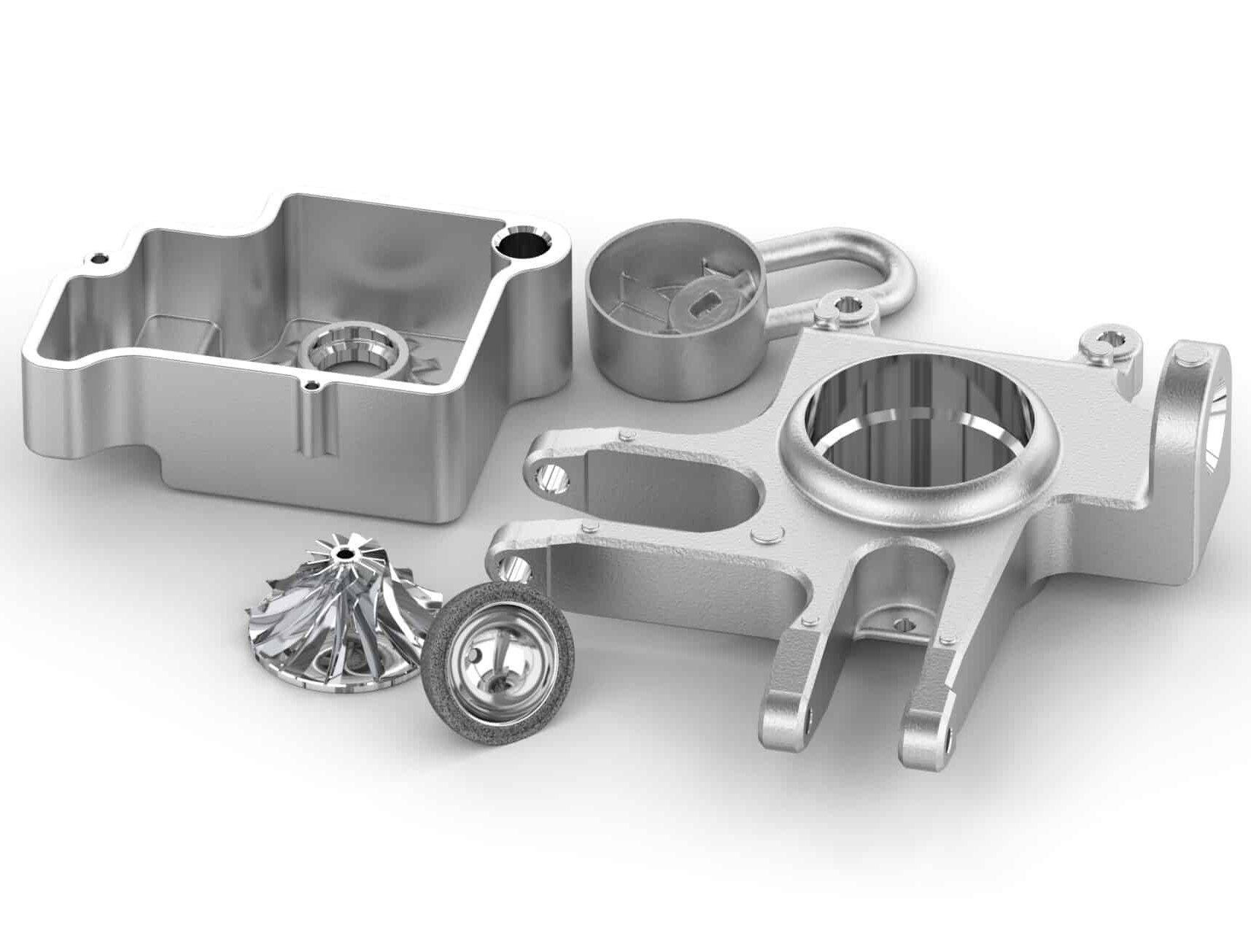

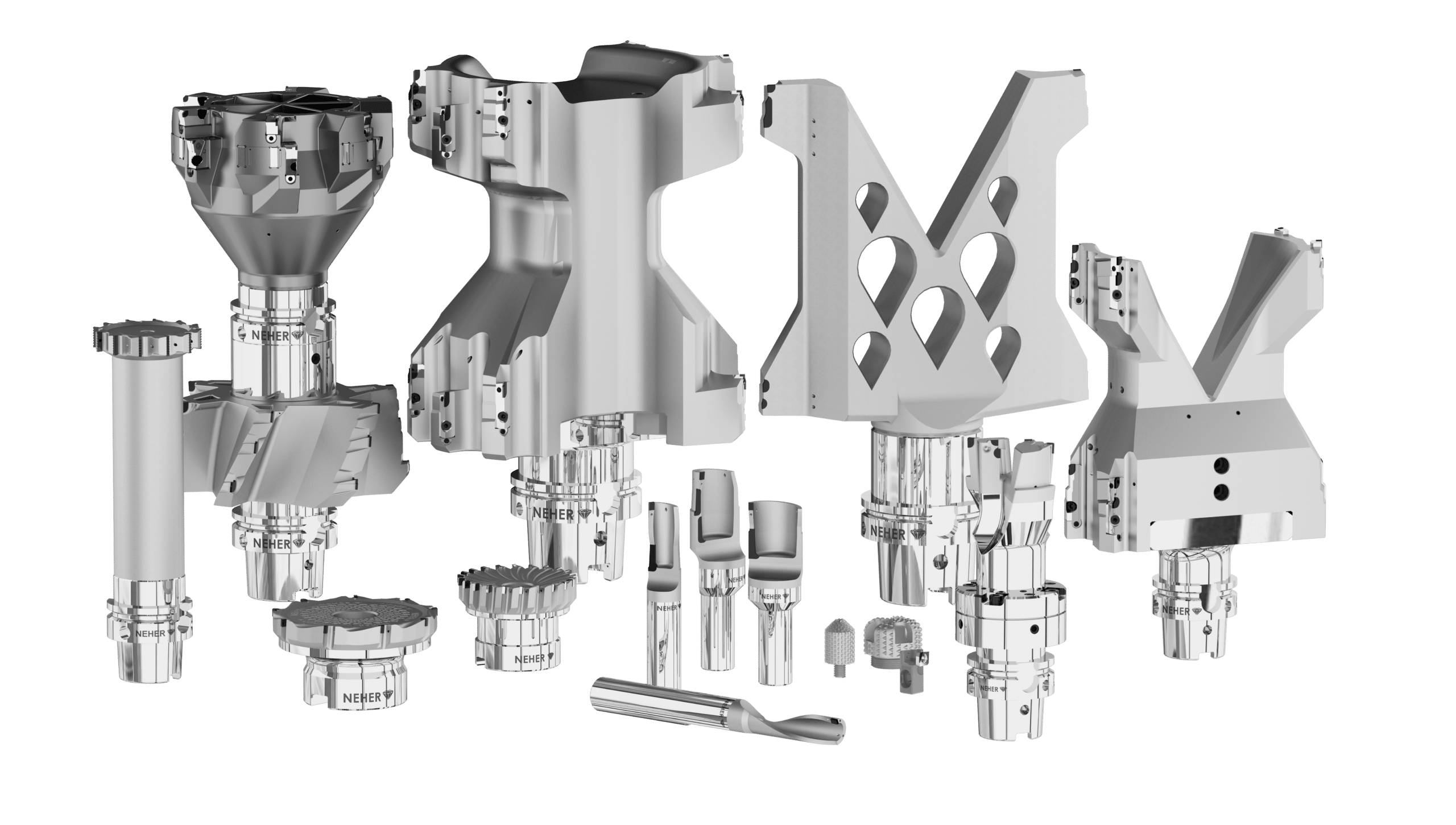

The NEHER GROUP recognized the clear advantages of additive manufacturing. It enables customers to produce cost-effective prototypes from various materials such as aluminum, steel, titanium, Inconel, cobalt-chrome and plastics as early as the product development phase. Additive manufacturing also offers the great advantage of producing components with near-net-shape details. Process and tool costs can be reduced, especially for difficult-to-machine materials such as titanium and Inconel, even in series production. Take a look at our catalog for a deeper insight into our products.

NEHMO DUAL - a revolutionary technology!

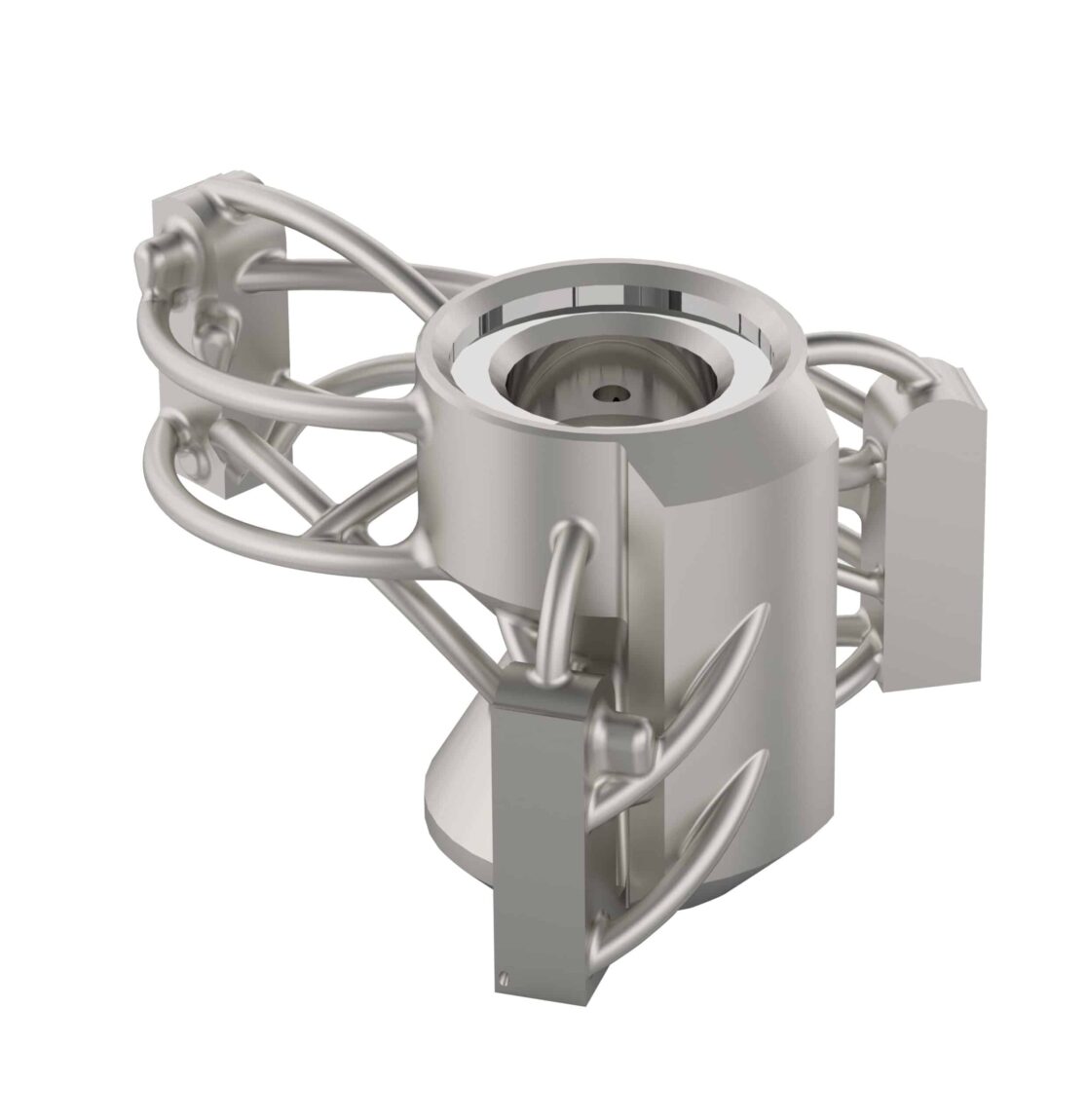

When manufacturing products using the 3D printing process, geometries can be realized which cannot be created in conventional manufacturing.

This type of manufacturing has also been implemented at NEHER for some time.

Special features, such as the design of the base body in a so-called honeycomb structure or with spiralized internal cooling, are nowadays indispensable.

- Challenge

- Cooling channels specially developed for minimal lubrication technology

- No possibility of conventional manufacturing

- Solution

- Innovative 3D printing

- Possibility to map complex structures inside the milling head

All advantages at a glance

- Very short delivery times

- Extensive "knowhow" in the field of additive manufacturing

- Rapid prototyping without a mold or the like

- Choice between different materials possible

- Savings in process and tooling costs due to finished or near-net-shape production of components

- Savings in storage costs, e.g. for spare parts

- Design and production of geometries that cannot be produced conventionally

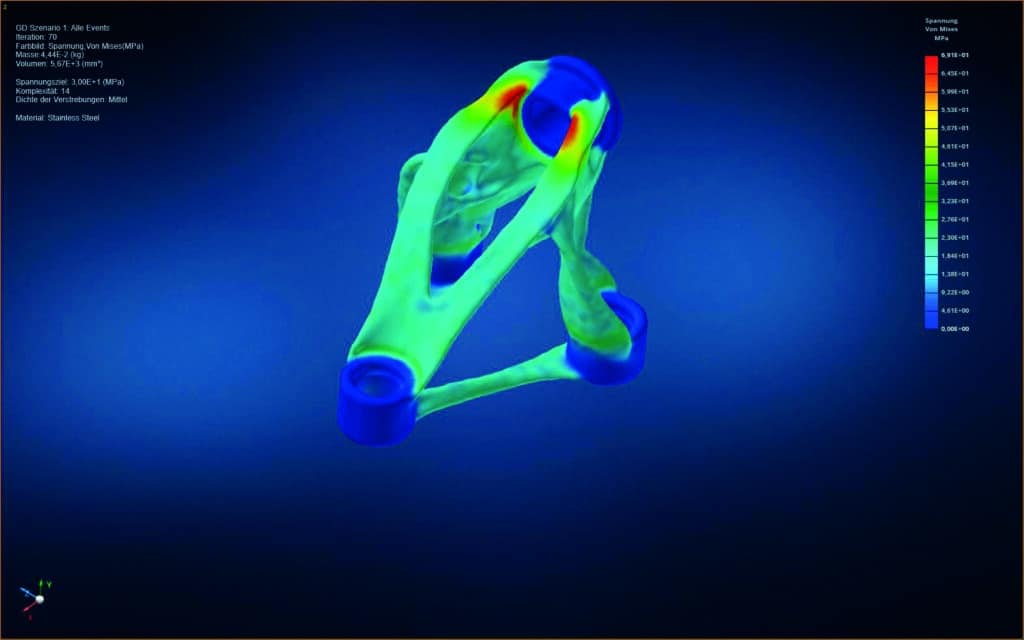

- High potential for component optimization in terms of lightweight construction

- Acceleration of development processes

- Production of molds with near-contour cooling

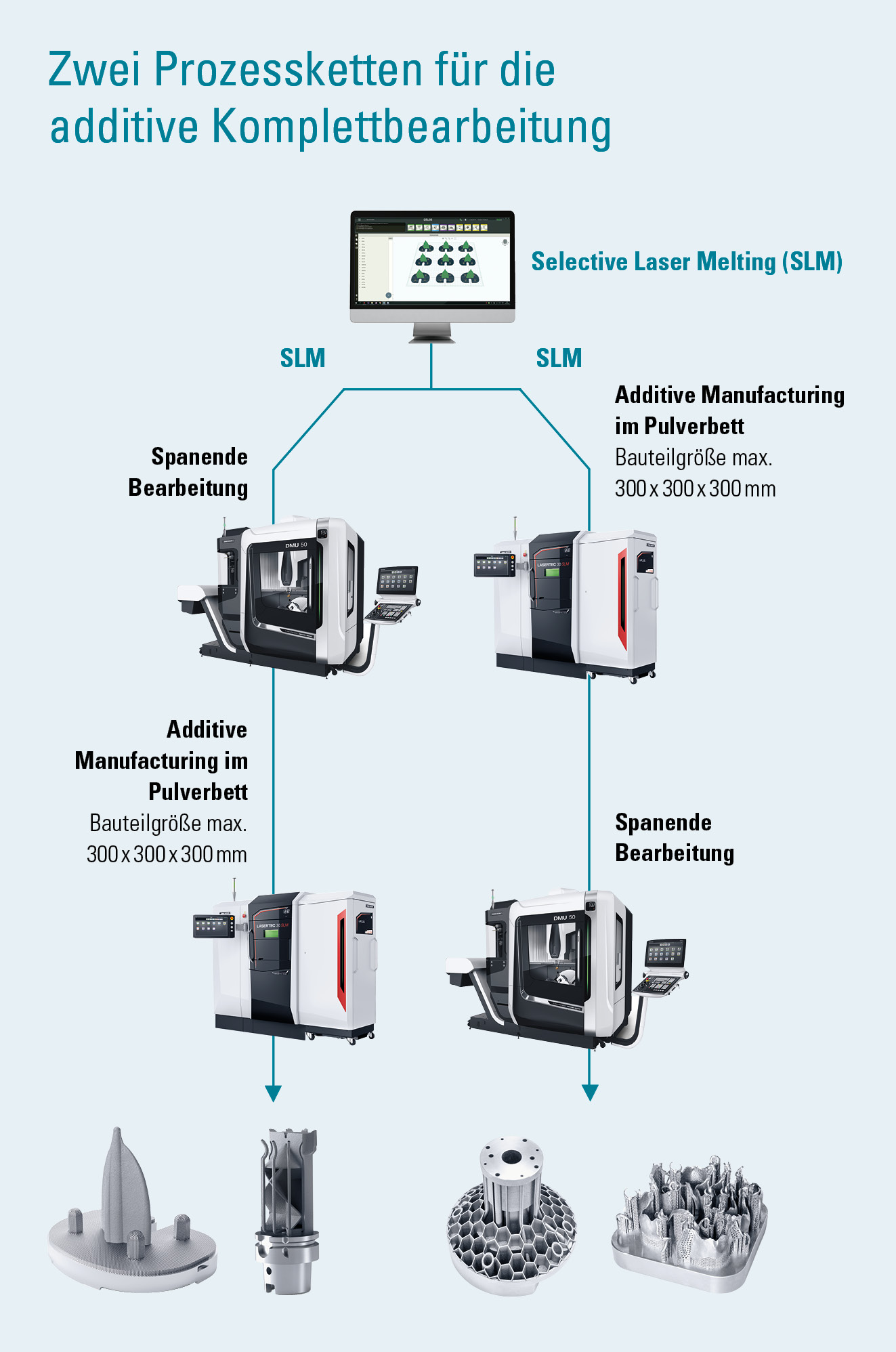

Two process chains with additive manufacturing in the powder bed

DMG MORI offers the LASERTEC 30 SLM for additive manufacturing in the powder bed (Selective Laser Melting). The second generation of this machine offers an installation space of 300 × 300 × 300 mm and presents itself in the new stealth design for optimum ease of use.

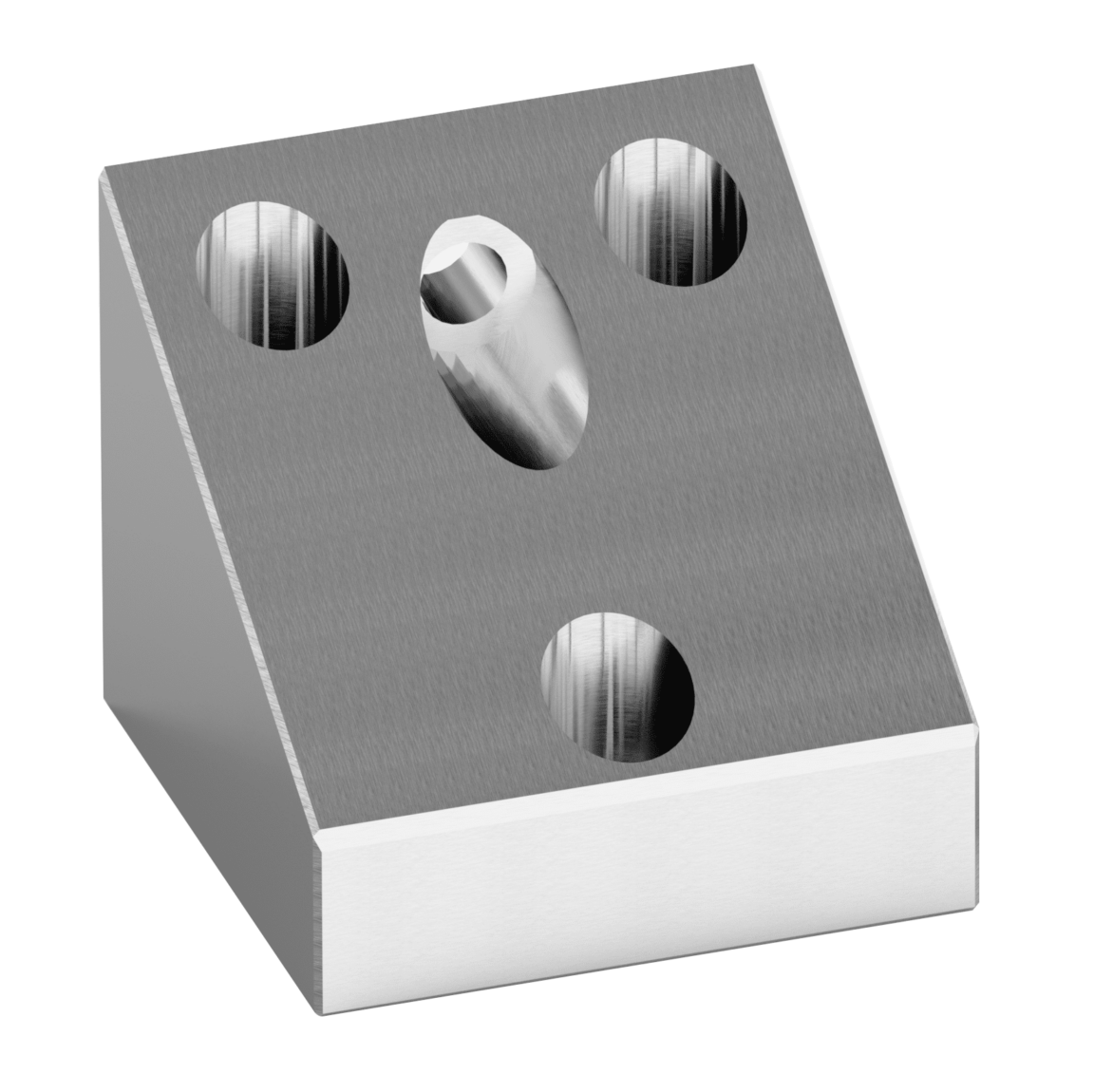

Powder bed technology opens up two process options: Additively manufactured workpieces can be reworked on a milling machine to achieve the required surface quality. Additive manufacturing without support structures is also possible. In this case, the component is printed onto a conventionally machined part, whereby the component is finished. The integrated CELOS software solution for CAM programming and machine control complements the process sequences of the LASERTEC 30 SLM. Thanks to the efficient flow of information and intuitive operation, the uniform interface offers optimum processes both before and after the processing of additively manufactured components.

The NEHER GROUP team optimizes manufacturing processes for customers from the automotive, aerospace and mechanical engineering industries and develops individual solutions from the idea through prototype construction to series production. The possibilities and capacities in metal laser melting have been expanded by the NEHER GROUP after an extensive field test together with DMG MORI by a LASERTEC 30 SLM 2nd generation.

Special tools with special requirements from the 3D printer.

Contract manufacturing

Additive / Generative

Due to our diverse range of products

and extensive manufacturing capabilities,

we have a wide array of technologies and

machinery at our disposal. In addition to

conventional CNC-controlled turning and

milling centers, we also have two 3D metal

printers along with corresponding measuring

technology. We take pleasure in utilizing our

expertise to create tailored components

for our customers.